(Thanks to Josh Montgomery http://www.minutemanreview.com/ for collaborating to provide this information.)

(Thanks to Josh Montgomery http://www.minutemanreview.com/ for collaborating to provide this information.)

Knives can be used for a variety of uses including what electricians need daily on the job. There are, however, knives designed specifically for use by electricians. These electrician knives are insulated to significantly reduce the chance of an electrical shock.

While electricians can choose a multi-tool or a pocket knife, an electrician knife intended to better suit the job is recommended. A good quality, sharp knife always makes work easier and protects the user from injury.

While electricians can choose a multi-tool or a pocket knife, an electrician knife intended to better suit the job is recommended. A good quality, sharp knife always makes work easier and protects the user from injury.

Uses of An Electrician’s Knife

The primary use for an electrician knife is cutting wires and cables and stripping off their plastic insulation. It is also frequently used to cut boxes that carry electrical equipment.

The knife is perfectly designed so that it does not harm the core wire when stripping off the insulation layer. Its blade is sharp enough to cut through the insulation layer while its edge ensures that the core wire is not cut.

An electrician’s knife cannot only be used in construction sites but also for chipping and carving wood at the farm or cabin. A multi-function knife can be used to screw or drill a hole with ease. This makes it easy to pass wires through the wood.

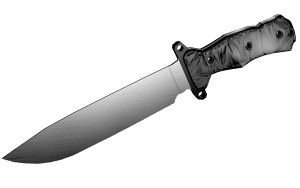

Common Blades for Electrician’s Knives

There is a myriad of blades available for electrician’s knives. Each of the blades is designed to tackle a specific task. It’s important for electricians to understand how these blades differ and which blade should be used for which application. Some common blades include:

Coping Blade

A coping blade features a straight spine which comes in handy when you need to create parallel lines. It also features a thin sharp point designed for stripping wires and cutting open electrical boxes.

Sheepsfoot Blade

A sheepsfoot knife comes with a straight edge with a bowed spine. The design of this knife makes it safe as it does not have a tip that may pierce. It is typically used to cut the hooves of sheep, but it is also used to carve wood, sharpening a knife and most importantly – it prevents users from accidentally puncturing themselves while doing electrical work (like cutting boxes that contain electrical equipment). As a knife for cutting hooves, it is can be used to teach kids since it is safe. Additionally, electricians can also use it to drill holes.

Spear Point Blade

A spear point blade is a simple symmetrical design that sports a sharp edge and sharp point. The knife is made with double edges, and it is mainly used for piercing. In some contexts, the knife is referred to as a dagger.

There have been different alterations on the design of this knife with some being foldable and some fixed. However, due to the double-edged nature of this knife, it is not easy to carry around each day. For electrical work, the knife can cut through hard materials, while the more obtuse edge (as opposed to the ground acute edge) can be used for rough work. Think making a clearance in thick walls to find and uncover electrical installation and wires.

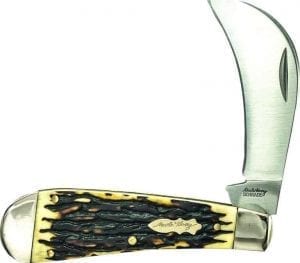

Hawkbill/Pruner Blade

As the name suggests, the hawkbill/pruner knife is used for pruning, but besides that, it is used to cut strings, linoleum, roofing paper, and carpets and cutting wires. Generally, the knife is large and curved. Most designs of this knife sport a single blade but others come with an extra blade which is used as a pruning saw.

The knife entered the electrical field when linoleum was developed. It is normally used to strip insulation from wires.

Seasoned electricians normally use a hawkbill knife when stripping wire, with the curved part coming in handy preventing the wire from slipping off when you are stripping towards yourself.

Other Common Knives Electricians Use

Other knives Electricians use fall in either of two categories: utility knives and pocket knives.

Utility knives are common in trade and construction related tasks. In the electrical field, these knives are referred to as razor knives seeing that they feature a razor blade. The razor blade can be removed and replaced. Each knife comes with a storage space where you can keep additional blades.

Utility knives are economical, and you can buy them when you are on a budget. Again, you do not have to sharpen the knives, when the knife gets blunt, you replace the blade.

Pocketknives are not as common with electricians, but they are useful when the electrician is trimming and does not need all the tools. When you are trimming the switches and plugs, you only need a few tools, and this is where a pocket knife comes in.

Choosing an Electrician’s Knife

The right electrician’s knife is one that meets your needs. Some factors to consider when shopping include:

- Your Specific Needs: Electricians do not have the same requirements. While some electricians love long and fixed knife models, others prefer foldable and lightweight knife models. The former loves having a heavy-duty knife that does not weigh on their pockets.

- Blade Style: Knives can be foldable or fixed. Foldable knives are short and thick and can fit in your pocket while fixed knives are thin and long. If you will be using your knife often, a foldable knife comes in handy.

- Size and Weight: If you wish to carry your knife every day, it needs to be as light as possible and small in size. A knife that weighs between 3 and 5 ounces is ideal for daily use. There are heavier models for electricians who need heavy duty knives. However, when choosing knife size and weight, you have to consider the state regulations since there are state laws regarding the length of blade that can be carried either open or concealed. A knife with a 3-inch blade is an excellent length for daily use.

- Blade Material: The material used to make the blade determines the hardness, durability and edge retention qualities of a knife. The knife should withstand the wear and tear of everyday use for a good period of time. High carbon steel is excellent at retaining sharpness and sharpens quickly, but it is susceptible to rust and discoloration. Stainless steel is a better version of high carbon steel with the advantage of not rusting or discolouring. Titanium is another common blade material. The material lasts longer than stainless steel, has better edge retention and is generally easy to sharpen. Ceramic is light and tough, but it is more brittle than other materials.

- Handle Materials: The handle of the knife determines the comfort and ease of use of a knife. A good handle should be durable and offer a rough texture for a firm grip. Common materials include carbon fiber, fiberglass reinforced nylon, Zytel, G10 and Micarta, metal, Delrin, titanium, and nylon.

Safety Features: Folding knives come fitted with safety features such as a locking mechanism. Many have a liner style lock which electricians can rely on. A finger guard will ensure your finger does not slip and get injured. For those who are left-handed, make sure that you have a knife with a double ground spur for your safety.

In addition, chose a versatile knife, one that you can use for different applications. This does not necessarily mean that you have to get a multi-tool. Many great knives can be used for various functions. There is a great selection of electrician’s knives to select from so when shopping, take your time and choose the best.

Josh Montgomery, Guest Contributor

Josh Montgomery is a proud resident of Davenport, Iowa, where you can find him doing all sorts of both indoor and outdoor work including assembling survival gear, poking and tinkering in his workshop, and taking care of his two labradors Nancy and Charles along with his extraordinary wife.